5kW Liquid Cooled FC System VL

This fuel cell stack is the entry model of the liquid cooled fuel cell stacks from Horizon Fuel Cell Technologies. This fuel cell stack is the lowest minimum power we recommend for use in forklifts, small tractors, and other low-end commercial and industrial applications. The liquid cooling of a fuel cell stack enables it to operate in more variable environments where a vehicle, like a forklift, may frequently go from having a full load to ferrying zero cargo. In such use cases the liquid cooling helps the fuel cell stack to maintain a more consistent optimal temperature, which enables the stack to operate for more hours (even continuously) throughout a day. Because of the commercial and industrial use cases for liquid cooled stacks they also offer more power than air cooled stacks.

5kW Liquid Cooled Stack VL-Series

Additional Information

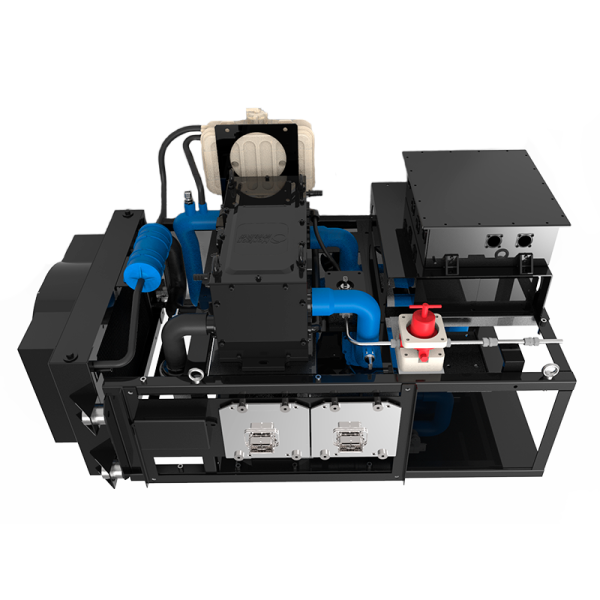

It is important to note that the liquid cooled fuel cell stacks which Horizon sells are systems instead of either a fuel cell stack or a fuel cell stack and a controller. Liquid cooled fuel cell stacks typically come with an air filter, air flow meter, hydrogen intel solenoid valve, humidifier, throttle valve, radiator, ion exchange, controller, fuel cell stack, fill water tank, fuel cell 24V water pump, constant voltage DC, and blower to bring air into the fuel cell stack.

Please fill out a quote request form so that we can set proper delivery and pricing expectations. It is important to note that liquid cooled fuel cell stacks are larger and heavier than air cooled stacks, because the liquid cooling does add weight to a fuel cell system. If you are uncertain whether a 5kW air cooled stack will work better for your project, then please feel free to mention that in the quote request form so that we can cover that issue with you.

List of VL-05 components and their functionality:

- Air filter (Prevents damaging size particles from entering fuel cell)

- Air flow meter (Monitoring feedback of air flow)

- Humidifier (Adds humidity to the air entering the stack)

- Radiator (Removes excess heat from the system

- Ion Exchange (Absorbs ions in the coolant and reduce the conductivity of the coolant)

- Controller (Control system, system and vehicle communication)

- Fuel cell stack (Oxygen and hydrogen react to produce power)

- Fill water tank (Filling water and purge air for the fuel cell system)

- Fuel cell 24V water pump (Powers the cooling cycle of the fuel cell)

- Constant voltage DC (Charge the 48V power battery)

- Blower (Provide air for the system)

In addition to the above components, the fuel cell system is also equipped with some sensors to feed back the temperature, pressure and humidity signals of the controller system during operation.

The internal oxygen supply system and cooling system components of the system also need to be connected with silicone tubes and multi-way joints to ensure the flow of fluids in the system.

The fixing of the various parts of the system requires the support of a bracket, and the whole system needs a fixed frame, which is connected and fixed together by the frame. Finally, many electrical parts in the system need to be connected with high-voltage wiring harness or low-voltage wiring harness.

5kW Liquid Cooled Stack VL-Series Quick Product Facts

System Rated Power

This system power output is 5kW.

Stack Rated Power

The fuel cell stack gives 6kW of output power.

Number of Cells

This fuel cell stack is composed of 65 fuel cells.

Voltage Current Output

The voltage current output of the fuel cell stack is 48 volts at 125 amperes.

DC output voltage

Direct current output voltage reaches 48 volts.

Fuel Cell Efficiency

Minimal fuel cell efficiency at rated power is 42%.

Ambient Temperature

The fuel cell stack operates best in a temperature ranging from 14 to 113° F / -10 to 45° C.

Stack Operating Temperature

The fuel cell stack operates best in a temperature ranging from 60 to 70°C / 140 to 158°F.

FC System Weight

The stack (including DC and radiator) weighs 374lbs / 170kg.

System dimensions

This fuel cell system dimensions are 630 x 560 x 610mm / = 24.8 x 22 x 20,5″

Hydrogen Pressure

Hydrogen must be fed into the fuel cell stack at a pressure of 0.6-1.0 bar.

Hydrogen Purity

A fuel of gaseous hydrogen at a minimum purity level of 99.97% is required.