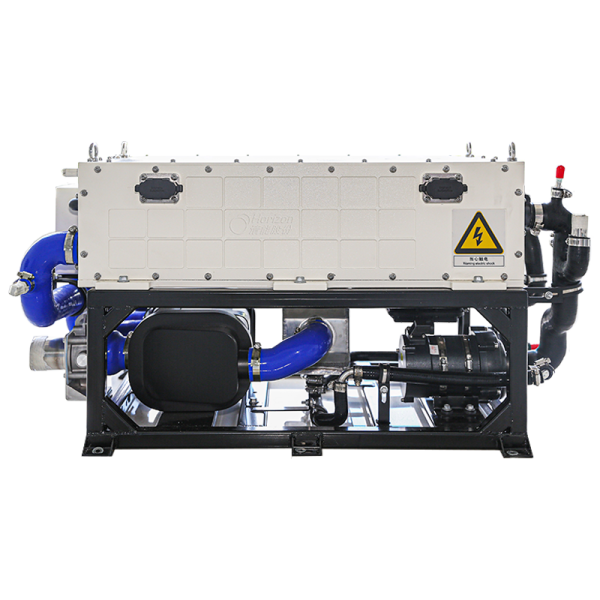

120kW Liquid Cooled Hydrogen Fuel Cell VL-Series

The 120kW is an advanced hydrogen fuel cell system that Horizon sells, and this PEM fuel cells system has the highest power rating of any fuel cell stack that Horizon offers. It is the same stack that is currently powering Class 8 trucks around the world, and it is capable of meeting energy requirements anywhere in the mobility sector. If the intended use case for this fuel cell requires more than 120kW, then it is possible to link multiple fuel cell stacks together in order to achieve the needed power requirement. This fuel cell stack can also replace an existing gasoline or diesel engine, which would enable such a vehicle to be transformed into a zero emission vehicle (ZEV). There is currently no powertrain that is more environmentally friendly than hydrogen fuel cell technology, especially in hard to abate parts of the global economy.

120kW Liquid Cooled Fuel Cell VL-Series

Additional Infromation

Because of the use cases for this fuel cell stack you will need to fill out a quote request form so that we can provide you with any information you need in order to integrate this product into your project. It is important to reach out to us for fuel cell stacks that produce more than 20kW of power, since this enables us to set proper delivery expectations. As with the other liquid cooled stacks, this fuel cell system comes with an air filter, air flow meter, hydrogen intel solenoid valve, humidifier, throttle valve, radiator, ion exchange, controller, fuel cell stack, fill water tank, fuel cell 24V water pump, constant voltage DC, and blower to bring air into the fuel cell stack.

Fuel Cell and Hydrogen

Safety Requirements

Do not attach or detach power cables when the fuel cell stack is turned on.

Warranty is void if the fuel cell stack is dismantled or otherwise modified.

Hydrogen is a colorless, odorless, and flammable substance. Always operate and store the fuel cell stacks and hydrogen storage canisters in an area with ample ventilation.

Fuel cell systems should always be equipped with a highly accurate hydrogen sensor to detect any hydrogen that has escaped within the system or from the hydrogen storage canister.

Please refer to the VL II-120 User Manual to see the full list of the safety requirements for the product.

Fuel Cell and Hydrogen

Safety Requirements

Do not attach or detach power cables when the fuel cell stack is turned on.

Warranty is void if the fuel cell stack is dismantled or otherwise modified.

Hydrogen is a colorless, odorless, and flammable substance. Always operate and store the fuel cell stacks and hydrogen storage canisters in an area with ample ventilation.

Fuel cell systems should always be equipped with a highly accurate hydrogen sensor to detect any hydrogen that has escaped within the system or from the hydrogen storage canister.

Please refer to the VL II-120 User Manual to see the full list of the safety requirements for the product.

120kW Liquid Cooled Fuel Cell VL-Series Quick Product Facts

System Rated Power

This system power output is 120kW.

Stack Rated Power

The fuel cell stack gives 150kW of output power.

Number of Cells

This fuel cell stack is composed of 500 fuel cells.

Voltage Current Output

The voltage current output of the fuel cell stack is 300 volts at 500 amperes.

DC Output Voltage

Direct current output voltage reaches 500 to 700 volts.

Fuel Cell Efficiency

Minimal fuel cell efficiency at rated power is 47.8%.

Ambient Temperature

The fuel cell stack operates best in a temperature ranging from -22 to 113° F / -30 to 45° C.

Stack Operating Temperature

The fuel cell stack operates best in a temperature ranging from 70 to 85°C / 158 to 185°F.

FC System Weight

The stack (including DC and radiator) weighs 639lbs / 290kg.

System dimensions

This fuel cell system dimensions are 1200 x 680 x 630mm / 47 x 26 x 24″.

Hydrogen Pressure

Hydrogen must be fed into the fuel cell stack at a pressure of 1.1-1.3Mpag.

Hydrogen Purity

A fuel of gaseous hydrogen at a minimum purity level of 99.97% is required.

List of core VL-120 components and their functionality:

- Air filter (Filter the air)

- Air flow meter (Monitoring feedback of air flow)

- Hydrogen heat exchanger (Increase the temperature of reaction hydrogen)

- Intercooler (Reduce the temperature of the air entering the fuel cell stack)

- Humidifier (Adds moisture to the air entering the stack)

- Bypass valve (Divert excess air from the air compressor and protect the stack in case of emergency)

- Throttle valve (Adjust the internal operating pressure of the stack)

- Radiator (Take away the excess heat from the system)

- PTC heater (Heating for low temperature cold start)

- Water tank (Refill water to and purge air for the system)

- Deionizer (Absorbs the ions in the coolant, reducing the conductivity of the coolant)

- Low voltage distribution box (Provide low voltage distribution to the system)

- Controller (Control system, communication between system and vehicle)

- Fuel cell stack (Oxygen and hydrogen react to produce power)

Packing Information

| VL-05 | VL-10 | VL-30 | VL-40 | VL-65 | VL-100 | VL-120 | ||

|---|---|---|---|---|---|---|---|---|

| System rated power output (kW) * | 5 | 10 | 30 | 40 | 65 | 100 | 120 | *does not include cooling fan power and boost DC efficiency |

| Stack rated power output (kW) | 6 | 12 | 36 | 53 | 79 | 120 | 150 | |

| Number of cells | 65 | 90 | 150 | 220 | 330 | 500 | 500 | |

| Operating ambient temperature (℃) | -10 to +40 | -10 to +40 | -30 to +45 | -30 to +45 | -30 to +45 | -30 to +45 | -30 to +45 | |

| Storage ambient temperature (℃) | -40 to +60 | -40 to +60 | -40 to +60 | -40 to +60 | -40 to +60 | -40 to +60 | -40 to +60 | |

| Operating ambient humidity (%) | 0 to 95 | 0 to 95 | 0 to 95 | 0 to 95 | 0 to 95 | 0 to 95 | 0 to 95 | |

| Operating pressure (kPa) | up to 50 | up to 50 | 80 to 100 | 80 to 100 | 80 to 100 | 80 to 100 | 120 to 150 | |

| IP rating | IP54 | IP54 | IP67 | IP67 | IP67 | IP67 | IP67 | |

| Vibration noise (dB) | up to 80 | up to 80 | up to 78 | up to 78 | up to 78 | up to 78 | up to 90 | |

| Voltage current output | 125A@48V | 222A@54V | 400A@90V | 400A@132V | 400@198V | 400@300V | 500A@300V | |

| System dimensions (mm) ** | 630 x 560 x 610 | 630 x 560 x 610 | 742 x 686 x 637 | 890 x 600 x 520 | 970 x 600 x 516 | 1200 x 790 x 520 | 1200 x 680 x 630 | ** radiator, touch screen, booster DC or air compressor not included |

| System weight (kg) *** | 170 | 180 | 135 | 145 | 170 | 238 | 290 | *** booster DC not included |

| DC output voltage (V) | 48 | 48/80 | ||||||

| Boost DC output voltage (V) | 300 to 450 | 500 to 700 | 500 to 700 | 500 to 700 | 500 to 700 | |||

| System mass power density (W/kg) **** | 220 | 275 | 382 | 420 | 505 | *** booster DC not included | ||

| Fuel cell stack volume ratio power (kW/l) | 3.5 | |||||||

| Stack operating temperature (℃) | 60 to 70 | 60 to 70 | 70 to 85 | 70 to 80 | 70 to 80 | 70 to 80 | 70 to 85 | |

| H2 purity (% dry hydrogen) | 99,97 | 99,97 | 99,97 | 99,97 | 99,97 | 99,97 | 99,97 | |

| Average H2 consumption at rated power (m3/kWh) | up to 0,73 | up to 0,73 | up to 0,73 | up to 0,73 | up to 0,73 | |||

| Fuel Cell efficiency at rated power (%) | at least 42 | at least 42 | at leas 47,8 | at least 47,8 | at least 47,8 | at least 47,8 | at least 47,8 | |

| Hydrogen inlet pressure (Mpag) | 0,6 to 1.0 | 0,6 to 1.0 | 1,1 to 1,3 | 1,1 to 1,3 | 1,1 to 1,3 | 1,1 to 1,3 | 1,1 to 1,3 |

Please contact Sales for Pricing sales@robotixeducation.ca